Every company needs to have good technical and design knowledge that must be continuously and expertly applied in each production area. This represents a constant new challenge for us, which is successfully tackled each time, thanks to our company structure and innovation.

All pipes are cut and marked with their heat number or any other tag requested. The goods are treated in an internal area, by removing any traces of paint, rust or impurities.

We are also qualified in NDT tests, such as radiographic examinations, Dye penetrant, Magnetic Particle tests, PMI and hydraulic tests with the following tools: Rx equipment, bunker and dark rooms with automatic developer and scanner for digitalizing of the Rx films; Yoke for magnetic controls; Spectrometer for chemical analysis (PMI), thickness verification of the layers of paint and materials. We also carry out tests on finished plants, such as flushing oil and water circuits; empty and load functional tests for compressor packages.

After surfacing treatments (painting, pickling, etc.), carried out in a quiet area away from the production department, the final assembly of plants and components takes place. The goods are prepared for testing and shipping activities.

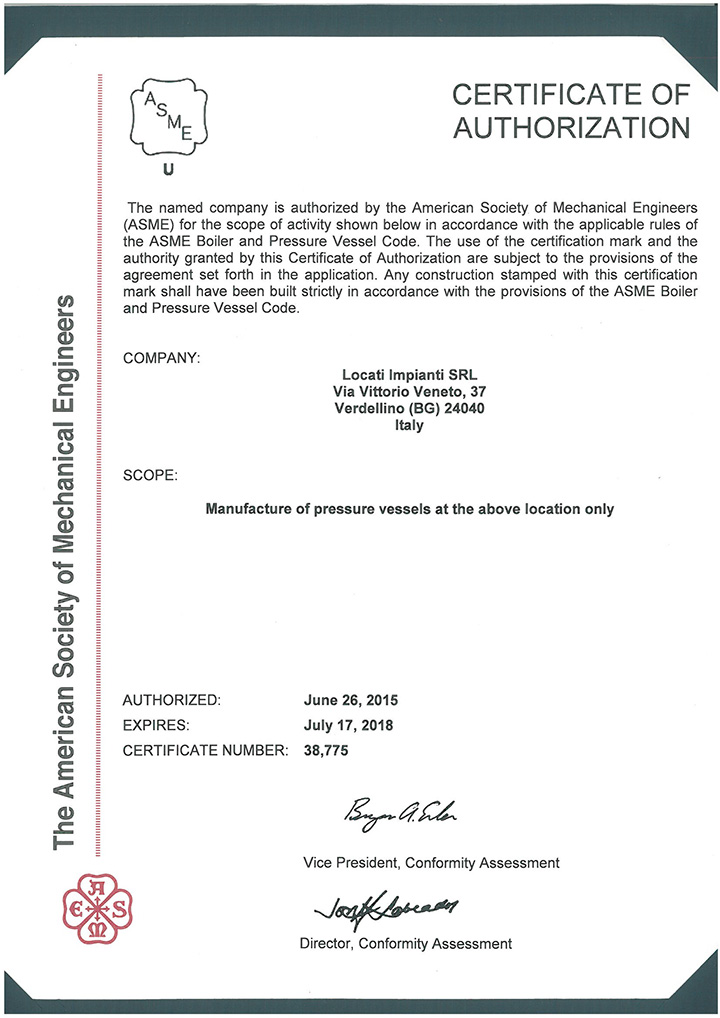

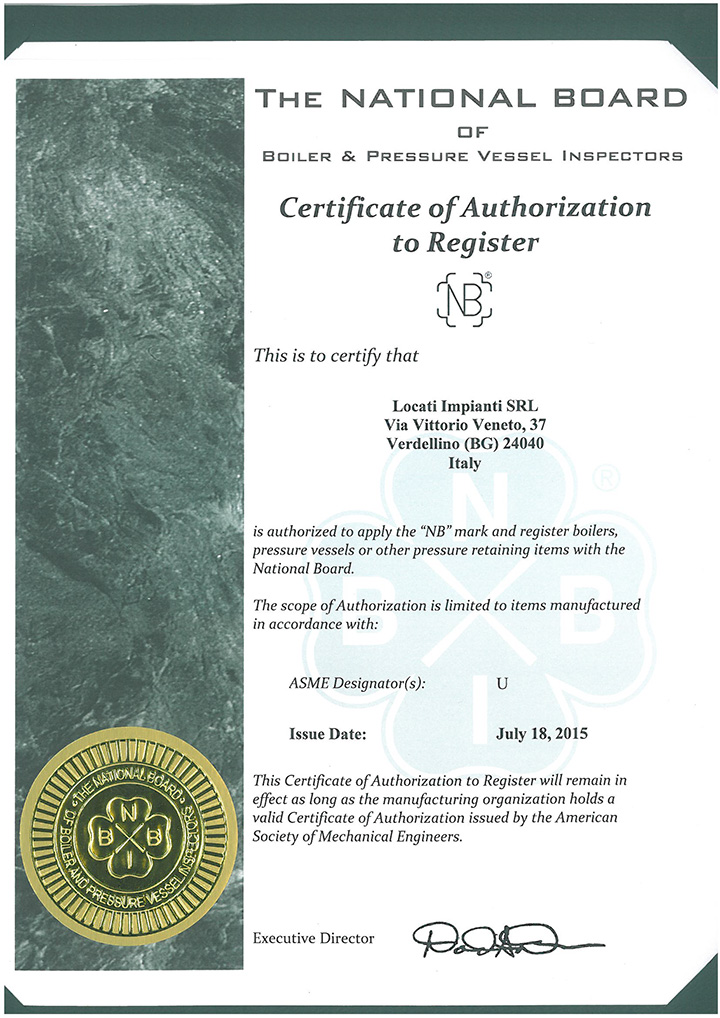

Locati Impianti srl is specialized in designing and manufacturing pressure vessels, filtration and liquid gas treatment plants, dosing system skids, lubrication systems, cooling systems and air/gas compressor packages for various market sectors including mechanical, chemical and petrochemical industries.